Vertical cuttings dryer can be used for many types of drilling mud, mainly used for oil-based and composite-based drilling cuttings drying. Similar to other solids control equipment, such as drilling fluid vibrating screen, drilling fluid centrifuge, cyclone separator, vertical drilling cuttings dryer, the processing capacity is also closely related to the mud viscosity. The viscosity of mud is determined by many factors, including solid content, particle size, drilling fluid type and drilling fluid temperature.

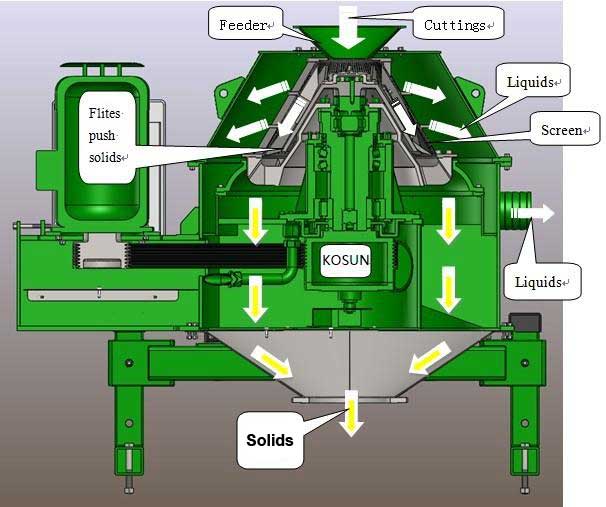

The Vertical cuttings dryer is a new type of solid-liquid separation and drying equipment. It does not need to add drugs, the screen basket is not easy to be blocked, it occupies a small area, is easy to install and operate, it has a strong processing capacity, and the solid-phase moisture content of the treated waste is low, the maintenance cost is low, and it has become the first choice for domestic and foreign companies to solve the solid-liquid separation and drying and the non-ground treatment of mud while drilling or abandoned mud pools.The Vertical cuttings dryer can effectively control the cuttings water content (6%-15%) and oil content (2%-8%) in the drilling mud, stabilize the liquid phase performance, and achieve the purpose of drying the mud without landing.

With the continuous improvement of environmental protection requirements, high requirements have been put forward for the disposal of cuttings on the drilling site. The emergence of drilling waste treatment and purification systems can not only solve the on-site environmental problems, but also can carry out the waste generated by the on-site solid control system. The secondary recovery treatment can retain useful mud while intensively solidifying the reprocessed drill cuttings to reduce the damage to the surrounding environment caused by field operations. The use of waste mud cake after drilling waste treatment: it can be used for secondary utilization such as brick burning and road paving.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com