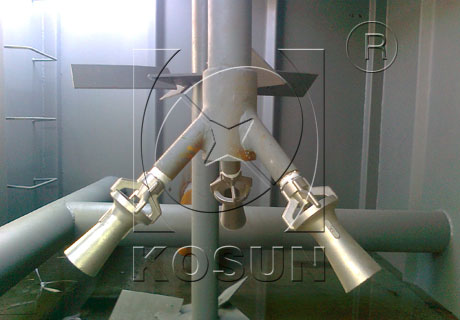

The vertical cutting dryer is designed based on the principle of centrifugal force, with unique three-foot suspension structure, which can avoid the unbalance of load, stable operation, good balance, low noise and high dehydration rate.Adopt flexible start, brake technology, long service life.

KOSUN vertical cutting dryer is suitable for the oil-base mud drilling waste management, through the principle of centrifugal separation, can effective recovery of the liquid phase composition in cuttings, makes the solid phase transition very dry, the drilling cuttings of oil-base mud recycling, reduce the cost of the drilling operation, also reduces the pollution to the environment, in line with international emissions standards and environmental requirements.It can be used for cuttings treatment in land and sea drilling.

Features and advantages of the vertical cutting dryer:

1. Effective solid-liquid separation, effective recovery of oil-based mud in drilling cuttings, significantly reducing solid phase emissions, and the solid phase oil content rate after treatment can reach less than 5%;

2. Effectively recover the oil based mud, and reuse the mud in the oil based mud circulation system, which can recover the mud lost due to the shale shaker running mud, moving derrick and screen blocking;

3. Common worn parts can be replaced from the top of the device;The belt can be replaced without moving any device.

4. Tungsten carbide anticorrosive and wear-resistant material is sprayed on the scraper of the internal turning body, which can prolong its service life and reduce maintenance cost;

5. Suitable for several years after drilling recovery treatment;

6. Realize the requirement of no mud landing on site, and reduce the cost of drilling oil based mud and waste disposal.

Kosun- China Solids Control Leader&Drilling Waste Management Expert

Tel.: +86 29 87304914

Email: sales2@adkosun.com

Contact person: Jinbo Zheng

Contact person: Jinbo Zheng