Vertical Cuttings Dryer

Vertical Cuttings Dryer is a kind of vertical centrifuge which is also named as VERTI-G Cuttings Dryer. It is regarded as to one of the most effective waste management equipment for oil- or synthetic- based drilling operations.

Kosun Vertical Cutting Dryer is applicable for recovery oil from the drilling cuttings in drilling industry .

In order to meet the international emission standards and environmental requirements. Kosun vertical dryer can cut down drilling costs and lessen environmental pollution by recycling mud in cuttings.

Processing capacity of 40-60T / h, after treatment of cuttings oil content (OOC) can be reduced to 5% (w / w) the following,

By using VERTI-G Cutting Dryer equipment,98% customers is very satisfied with the results.

How does the vertical cutting dryer work?

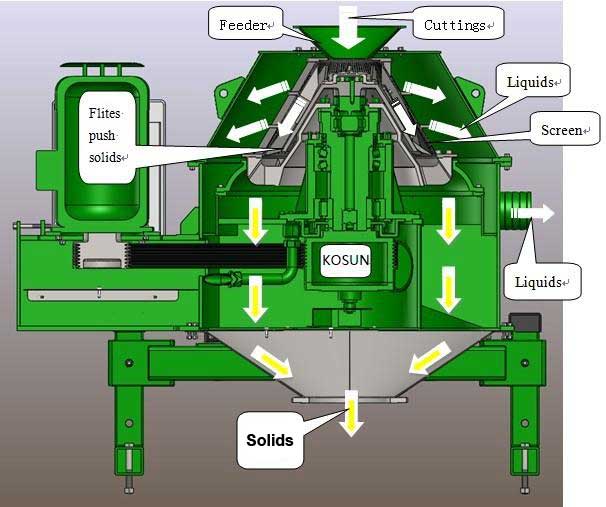

The vertical cutting dryer uses solid forces generated through mechanical rotation to separate solids and liquids. The drilling chips enter the space between the sieve basket and the scraper through the feed port and the fabric cone, and the drilling fluid flows through the material layer and the sieve into the collection tank along the cap under centrifugal force. The fluid is then discharged from the outlet pipe on both sides and the solids remain in the basket.

Due to the difference in speed between the screw blade and the sieve basket, the screw blade cuts the solid from the basket and then pushes it to the bottom of the basket so that the dewatered solids are continuously discharged into the collection funnel. The liquid phase will be further processed by Decanter Centrifuge Kosun also has it availalbe.

Kosun has more than 20 years experience in Drilling Solids Control Equipment and Drilling Waste Management Equipment with API, IADC, ISO and CE certificated.

KOSUN has been highly welcomed by customers by virtue of its high-quality products and best services. Welcome to contact with us.