Are you looking to better manage waste cuttings for your operation utilizing a Vertical Cuttings Dryer? KOSUN’s Vertical Cuttings Dryer continues to be the industry choice as the most reliable and efficient solution when dealing with waste cuttings.

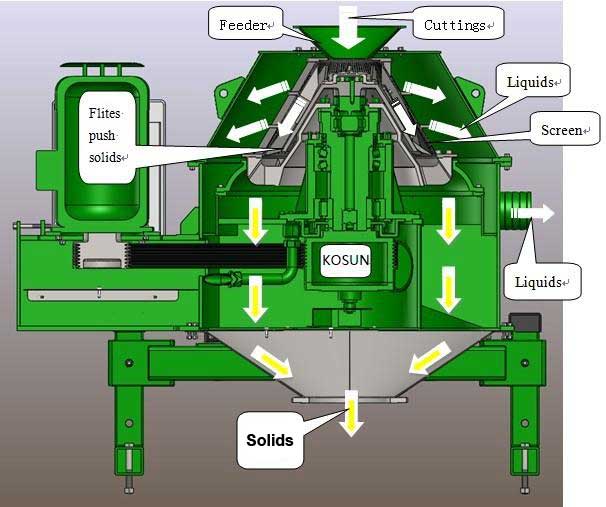

The drilling cuttings dryer (also known as rock cuttings dryer) produced by KOSUN is a single-stage continuous vertical scraper discharge centrifuge, also called a vertical drying centrifuge. It is an important piece of equipment for the mud zero discharge treatment of drilling waste in the oilfield. By centrifugal separation principle, it separates the solid and liquid phases. The cuttings dryer can effectively recover the liquid phase components in the drilling cuttings, making the solid phase exceptionally dry. And it can recycle the mud in the cuttings, performing particularly well in the treatment of oil-based mud and synthetic-based mud cuttings. So this helps reduce drilling costs and environmental pollution.

Different models of the dryer have processing capacities ranging from approximately 20 to 60 tons per hour. The oil content in the processed cuttings is below 5% (w/w) (OOC≤5%), meeting international emission standards and environmental requirements. It is suitable for cuttings treatment in both onshore and offshore drilling operations.

Tags: cuttings dryer, vertical cuttings dryer for sale, vertical cuttings dryer, manufacturer, factory, price

Related Links: