Vertical Cutting Dryer

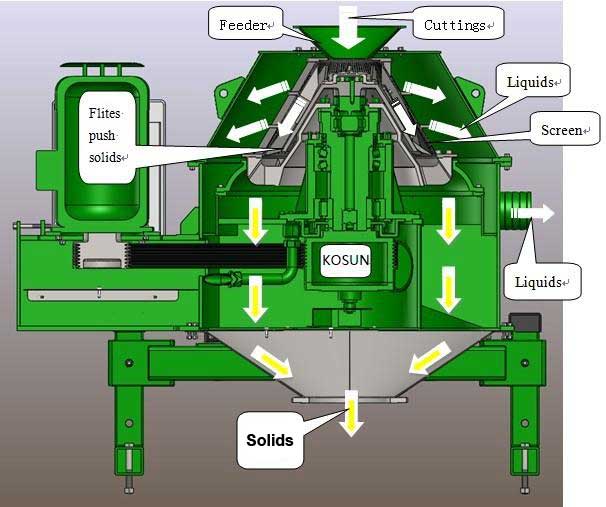

Vertical Cutting Dryer makes use of a unique force to dry solids from oil and other base fluids. The steel vessel catches the wet solids due to its stainless nature. The dry wastes are removed by the angles attached to the machine that rotate slightly slower than the bowl whereas liquid is thrown out through the bowl openings.

The Vertical Cutting Dryer makes the whole process easier and comfortable. It is highly effective in improving the efficiency of the machine at a comparatively lower rate. It accelerates the profits and well being of the company as it makes use of the left over mud and other sediments which would have been considered trash otherwise.

When we use dryer in drilling mud fields, it simplifies the work of Shale Shaker . It can provide a higher working efficiency guaranteed with simplification of further processing of purification of solids from the liquids.

The most impressive part of using a cutting dryer is its high adaptability. It can be easily used for all kinds of base mud including water, oil, and synthetic. It is one of the most effective machines, which are also environment friendly, and at the same time cheaper and cost effective. It hardly affects the environment negatively and causes no pollution.

The Major Functions of the Cutting Dryer include;

1- High Performance

It highly aids and improves the performance of the machine largely.

2- High speed centrifuge

3- Better Efficiency and Low Costs

What can be better than having better work done at low prices?

4- Extremely Helpful in cost cutting and pocket friendly

5- It simplifies the work of Shale Shakers

It largely simplifies and shortens the long working hours required in the Shale Shakers.

6- It is highly suitable for water-based mud, oil based mud and synthetic base mud.

7-It produces very less waste compared to other machines and produces much dryer end products

8- It can recover up to 95 percent of drilling fluids.