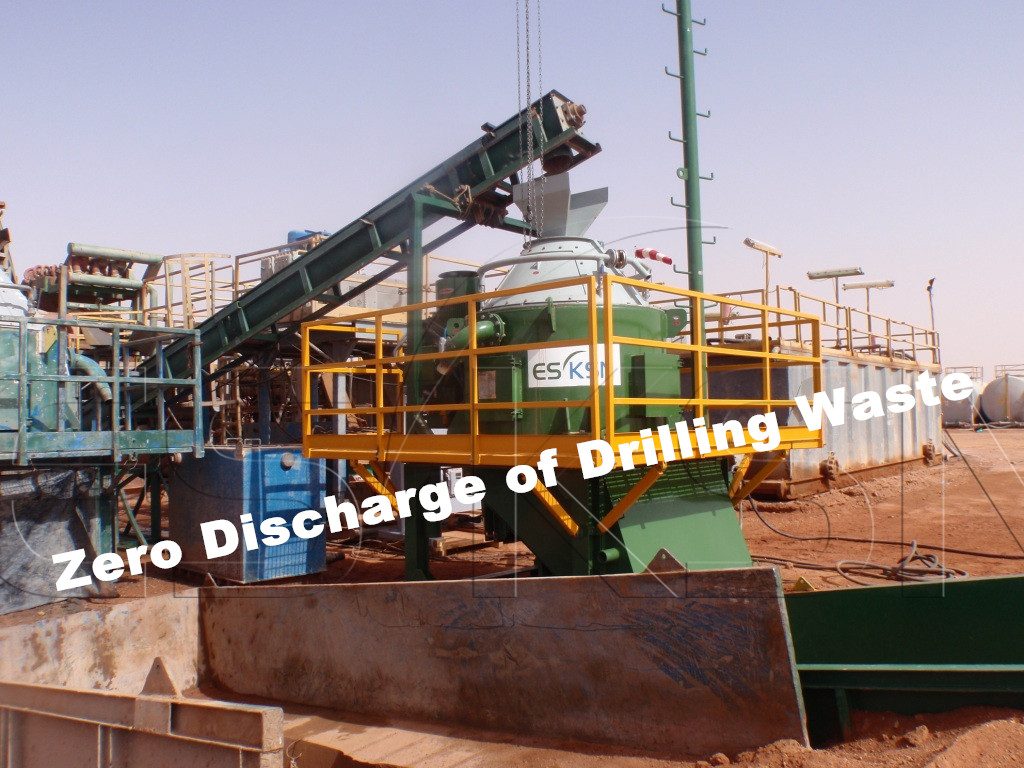

Xi ‘an KOSUN VD series drilling fluid vacuum degasser is a new special equipment developed by our factory on the basis of comprehensive degasser at home and abroad. It is suitable for all kinds of mud purification systems, which play a very important role in restoring the specific gravity of mud, stabilizing the viscosity of mud, and reducing the drilling cost. At the same time, it can also be used as a high-power agitator.

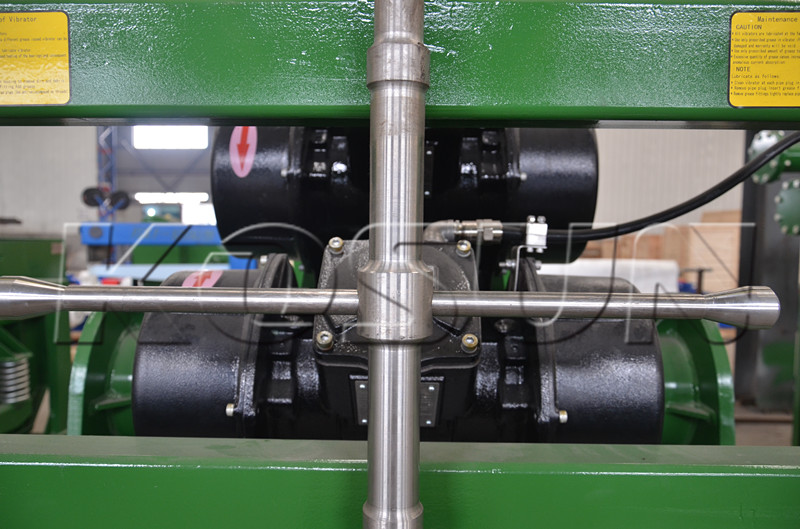

The degasser belongs to the drilling fluid vacuum degasser, that is, the suction effect of the vacuum pump is used to create a negative pressure zone in the vacuum tank. Under the action of atmospheric pressure, the mud enters the hollow shaft of the rotor through the suction pipe and then is thrown towards the wall of the tank in a spray shape through the window around the hollow shaft. Due to the impact of the collision and the separation wheel, the drilling fluid is separated into thin layers, and the bubbles immersed in the mud are broken. The gas escapes through the suction of the vacuum pump and the separation of the gas-water separator, the gas is discharged to the safety zone by the exhaust pipe of the separator, and the mud is discharged from the tank by the impeller. Since the main motor starts first, the impeller connected to the motor is in a high-speed rotation state, so the mud can only enter the tank from the suction pipe, and will not be sucked from the drain pipe.

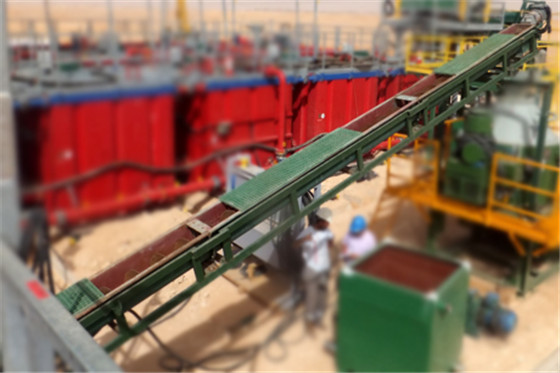

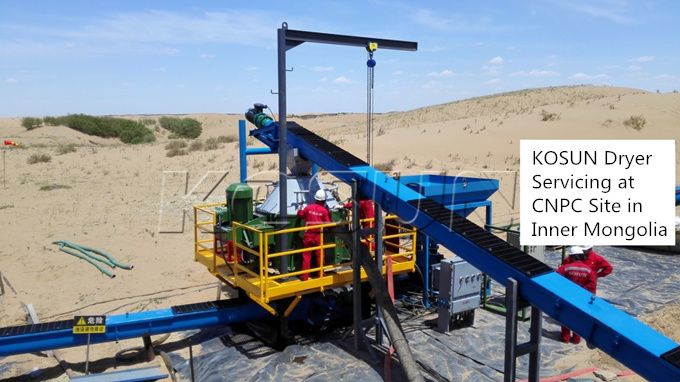

Last week, our factory shipped 8 pcs of drilling fluid vacuum degassers to foreign countries. As supporting equipment of drilling solid control equipment, this equipment provides a safety guarantee for drilling.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 13379250593

Contact person: Monica Li

Online consulting:

http://www.kosun.com

http://www.kosuneco.com