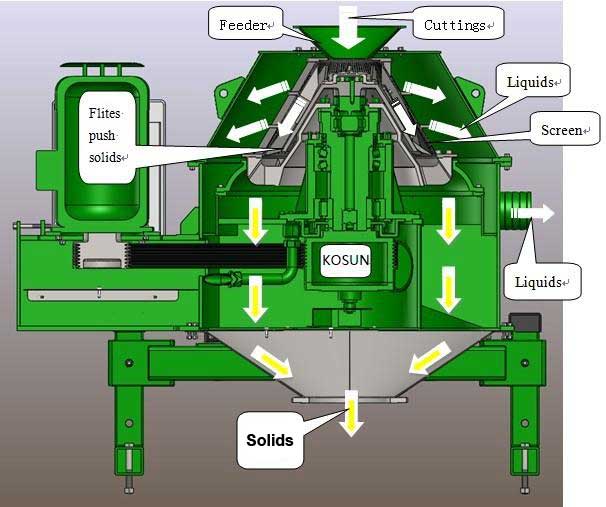

Vertical Cutting Dryer

Vertical cutting dryer is used for the purpose of recovering waste oil and cutting fluids from the system and bring them back into operation. In a drilling waste industry there is a heavy requirement of oil and as it can make the overall process very convenient.

According to the reports, 1 to 4 barrels of oil is required for 1 barrel of solid which is removed. If there is no cutting dryer installed in the system then all this oil will get wasted and thus increase the overall cost of the operation.

There are many benefits using vertical cutting dryer, here is how it can benefit you:

Make Operation environmental friendly

Wastage of oil can be very harmful for the nature. When there is no dryer installed in the system then it can cause a lot of waste of oil and damage the nature to a great deal. With the help of cuttings dryer all these waste can be monitored and you will get a very efficient way to work.

Cost effective

Reduction in waste can cause heavy losses. If you use the dryer into your system them most of the oil will be re-pumped into the system and there will be considerable reduction in the requirement of oil. It will also make system more efficient and bring out the best drilling.

Long service life

Dryers which are used for the purpose of controlling waste are all made from high quality material which can ensure that you get the best output from the service. If this system is not used then it can result it lots of losses and you will be also required to pump in a lot of oil into the system.

Reliable lubrication

Lubrication which is pumped back into the system is a lot more reliable and can provide you with better efficiency.

Kosun also have shale shaker, Mud Cleaner, shaker screen , DC Series Decanter Centrifuge, Screw Pump …….

Kosun vertical cutting dryer is well recognized and welcomed by clients all over the world. Welcome contact us if you need.