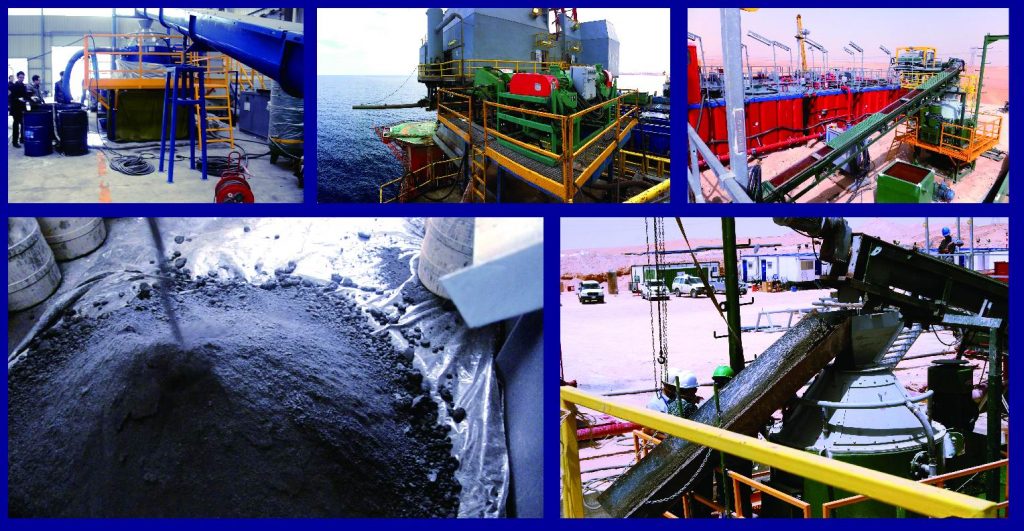

KOSUN drilling waste treatment system is divided into: water-based mud zero discharge system and oil-based mud zero discharge system according to its purpose. Its main equipment includes: drying shaker, Vertical cuttings dryer, drilling fluid centrifuge, screw conveyor, screw pump, etc., which can effectively control the water content of drill cuttings in the drilling mud (6%-10%) and stabilize the liquid Phase performance, to achieve the purpose of mud dry treatment without falling to the ground.

KOSUN Vertical cuttings dryer is a new type of solid-liquid separation and drying equipment. It does not need to add medicines. The screen basket is not easy to be blocked. It occupies a small area. It is easy to install and operate. The maintenance cost is low, and it has become the equipment for domestic and foreign enterprises to solve the solid-liquid separation and drying and the zero discharge treatment of mud while drilling or abandoned mud pools.

Filter presses and Vertical cuttings dryer are both important equipment for processing drilling mud waste to achieve solid-liquid separation and dehydration. Compared with the Vertical cuttings dryer, the filter press is an early dehydration device for drilling waste mud. It needs to be added with drugs, and the screen cloth is easy to block, the operation is complicated, the labor intensity is high, and the maintenance cost is high.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com